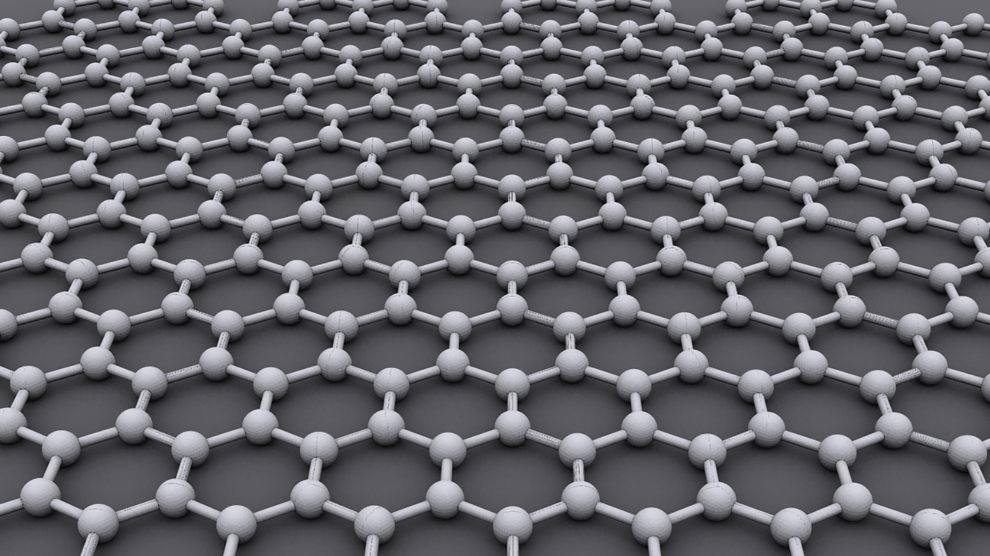

Graphene. Have you heard of it? If not, you're going to be hearing a lot more about it and what it can do for your golf clubs, shafts and balls -- and soon.

FOR GNN PLUS MEMBERS ONLY!

For as little as $8 per year, you can be a GNN Plus member and gain access to special members-only content like this, as well save potentially hundreds with member-only discounts through our partners. You'll also access our easy-to-use fantasy golf research tools.

Support independent media, and join GNN Plus today!

>>JOIN GNN PLUS NOW FOR AS LITTLE AS $8/YEAR!<<